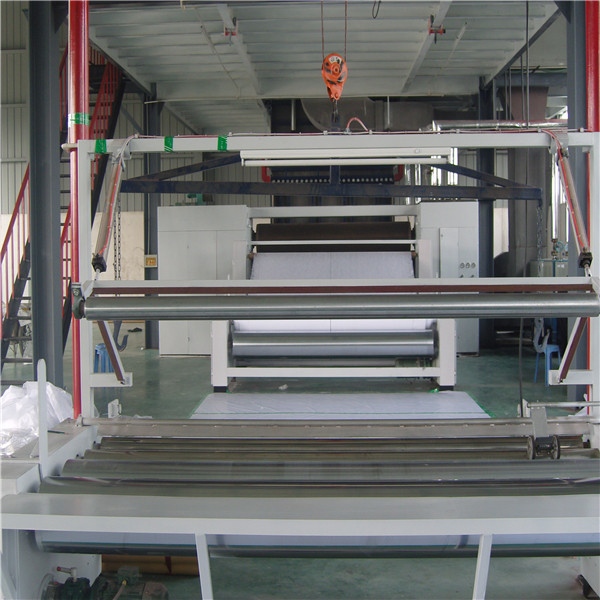

Meltblown nonwoven production line

-

Non-woven ss Production Line Sms Pp Spunmelt Nonwoven Fabric Production Line Spunbond Machine Non Woven Production Line

This polypropylene (PP) spunbonded nonwoven fabric production line has advantages of superior performance, beautiful color, and good quality. It can form a fibre web symmetrically and is complete in types. It can also add recycled material and stuffing to reduce the cost of products.

-

PP Spunbonded Meltblown Non-woven Fabric Machine Production Line for mask

PP Spunbonded Meltblown Non-woven Fabric Machine Production Line for mask Automatic bfe 99 pp meltblown nonwoven fabric Production Line non woven fabric making machine Meltblown non-woven fabric plays a role of isolation and filtration in the mask, protects the human body from the invasion of dust, bacteria, and viruses, reduces various infections, and effectively protects human health. Meltblown non-woven fabrics are mainly used for medical and health materials, filter materials, insulation... -

High quality professional melt-blown machine cutting non-woven production line

High quality professional melt-blown machine cutting non-woven production line

Process flow of polypropylene non-woven fabric processing equipment

Polypropylene non-woven fabric machinery and equipment: polymer (polypropylene + recycle)-large screw high temperature melt extrusion-filter-metering pump (quantitative delivery)-spinning (up and down drawing suction at the spinning inlet )——Cooling——Air traction——Net curtain forming——Up and down rollers (pre-reinforcement)——Hot rolling (reinforcement) of rolling mill——Winding——Inverted cloth slitting——Weighing and packaging——Incoming finished products Library

-

PP meltblown machine/Fastly delivery nonwoven fabric cloth produce line/melt blown fabric making machine equipment

PP meltblown machine/Fastly delivery nonwoven fabric cloth produce line/melt blown fabric making machine equipment

The production process of non-woven fabrics

1. Carded fiber

2. Fiber into a web

3. Fixation of the fiber net

4. Perform heat treatment

5. Finally, finishing and processing

Among industrial materials, non-woven fabrics have the characteristics of high filtration efficiency, insulation, heat insulation, acid resistance, alkali resistance, and tear resistance. They are mostly used to make filter media, sound insulation, electrical insulation, packaging, roofing and abrasive materials, etc. product.

In the daily necessities industry, it can be used as clothing lining materials, curtains, wall decoration materials, diapers, travel bags, etc.

In medical and health products, it can be used in the production of surgical gowns, patient gowns, masks, sanitary belts, etc.

-

PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment

PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment

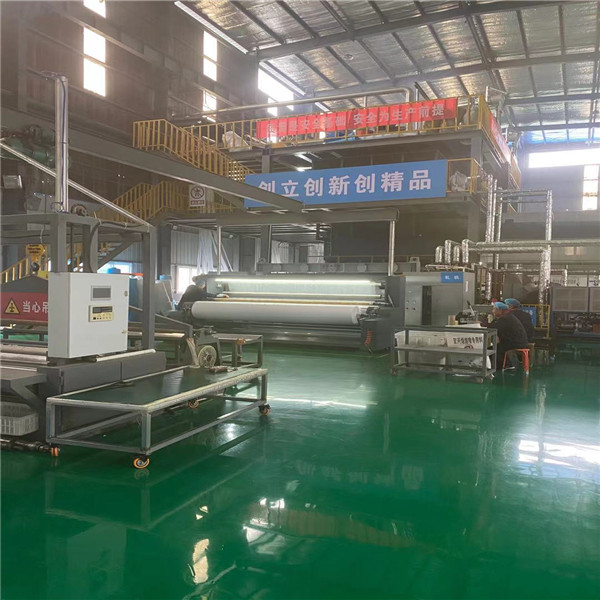

Our ss spunbond nonwoven production line adopts foreign advanced technology and experience,

Easy to operate, fully automated, PLC touch screen control, good product, high speed, high output. The equipment is usually 1.6 m wide, 2.4 m wide or 3.2 m wide, and it can also be customized according to the specific requirements of customers.

-

Non Woven Fabric Production Line SMS Spunmelt Non Woven Fabric Manufacturing Machine Fabric Production Line Manufacturing Equipment

1. The professional-grade non-woven equipment has been optimized in structure, and it is more compact for the first time. Non-woven equipment can integrate all the tools needed for non-woven processing into one equipment to achieve unified coordination. Therefore, professional-grade non-woven equipment is often small in size.

2. Stable operation is an important prerequisite for ensuring the output and quality of non-woven fabrics. Non-woven equipment that can continuously maintain stable operation can unify the quality of non-woven products and achieve better product price effects. Production plays a driving role.

3. The non-woven equipment adopts aluminum profile frame as the main body, the structure is sturdy and durable, not easy to rust, and has a long service life. It is relatively convenient to install and maintain. Therefore, the experience of using non-woven equipment is quite good. .

4. The automatic control mode of non-woven equipment can realize rapid and batch non-woven production, so it can greatly increase the output of non-woven products, reduce labor costs, and bring higher benefits to the enterprise. .

-

Non-woven fabric production line Melt blown fabric production line Non-woven fabric machinery

Maintenance and maintenance measures of non-woven equipment

1. Lubricating oil and engine oil should be added regularly to all oil filling points of the equipment. The timely replacement of lubricating oil and engine oil can effectively ensure the smooth operation of the machine and reduce the probability of failure.

2. The parts with tightness requirements should be checked in time every day. If there is a fault or problem, it should be repaired or replaced as soon as possible.

3. The chamber body guard plate of the non-woven equipment should be checked daily, and if it is damaged, it should be replaced in time.

4. The parts of the shot blaster guard plate, blades and impellers, directional sleeves, and blasting wheels must be inspected twice per shift. If any damage is found to the above parts, they must be replaced in time.

5. Electrical systems and transmissions need to be inspected twice a week to ensure the normal operation of the power system and prevent short circuits.

6. Regularly conduct clean and hygienic inspections, check the internal parts of the machine,

-

High Quality Spunbonded Pp Non-woven Fabric Production Line

The production process of non-woven fabrics

1. Carded fiber

2. Fiber into a web

3. Fixation of the fiber net

4. Perform heat treatment

5. Finally, finishing and processing

-

-

Best Price SMS Surgical Gown SMS Nonwoven Fabric machine High Standard Quality PP Spunbond Nonwoven Fabric Production Lin

1. Lightweight: Polypropylene resin is used as the main raw material for production, with a specific gravity of only 0.9, which is only three-fifths of cotton. It is fluffy and feels good…

-

SMS PP Melt-blown Nonwoven Fabric Production Line, Nonwoven Fabric Production Equipment

Among industrial materials, non-woven fabrics have the characteristics of high filtration efficiency, insulation, heat insulation, acid resistance, alkali resistance, and tear resistance. They are mostly used to make filter media, sound insulation, electrical insulation, packaging, roofing and abrasive materials, etc. product.

-

SMS Surgical Gown SS Nonwoven Fabric Machine High Standard Quality PP Spunbond Nonwoven Fabric Production Line

Spunbond non-woven fabric features: high strength, good high temperature resistance (can be used for a long time in a 150 ℃ environment), aging resistance, UV resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, mothproof, Non-toxic.