Smms Sms Nonwoven Fabric Production Line Sms Fabric Production Line sss ss Nonwoven Fabric Production Line

Non-woven fabric production process

Non-woven production line specifications

| SS(Prodnct width) | 1600mm | 2400mm | 3200mm |

| Equipment | 29x13x10m | 30x14x10m | 32x15x10m |

| Speed | 350m/min | 350m/min | 30m/min |

| Gram Weighht | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Yield(Products according to 20g/M2) | 9-10T/Days | 13-14T/Days | 18-19T/Days |

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

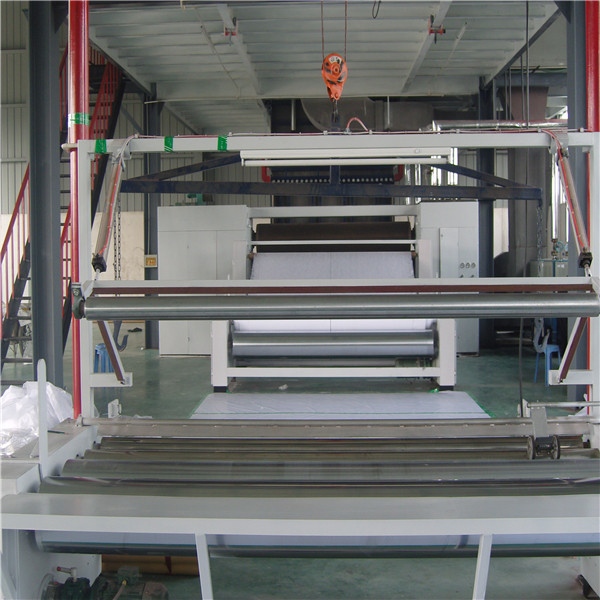

Production line system structure

The spunbond non-woven fabric production line is a very complicated but ingenious mechanical processing equipment. Below, the editor will show you the two major components of the spunbond non-woven production line in detail.

Two major components of the spunbond non-woven production line

Transmission system: The first is the transmission system of the spunbond non-woven production line. The transmission system includes two aspects, the internal transmission shaft and related parts, and the external transmission belt. The external transmission belt is mainly composed of a feeding device, a transmission device and a storage device. Each device corresponds to a different process of spunbond non-woven fabric production. The entire machine is driven by the huge internal drive shaft, and then it can achieve a very high-precision material transmission processing effect.

Control system: As the name implies, the control system is a system that controls the operation of the entire spunbond nonwoven production line. The reducer inside the spunbond nonwoven production line converts electrical signals into mechanical actions, and then supports the operation of the entire mechanical transmission components of the spunbonded nonwoven production line. At the same time, the spunbond nonwoven production line also has the conversion function of multiple control modes, for example, it can be adjusted between automatic, semi-automatic and manual, so as to meet the operation requirements of the spunbonded nonwoven production line under different production needs.

The above two major components form an integral spunbond non-woven fabric production line, which provides a powerful and reliable hardware guarantee for the production of spunbonded non-woven fabrics. With the continuous improvement of production technology, many spunbond non-woven production lines have begun to reduce prices and become popular, and many manufacturers have begun to introduce them. The whole set of equipment provided by our spunbond non-woven production line manufacturer is of high technical content, scientific price, and excellent quality, which will ensure that you will be satisfied with your use. If you are interested in our equipment, please feel free to visit our factory.