Short Lead Time for Mask Fabric Making Machine - PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment – Meiben

Short Lead Time for Mask Fabric Making Machine - PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment – Meiben Detail:

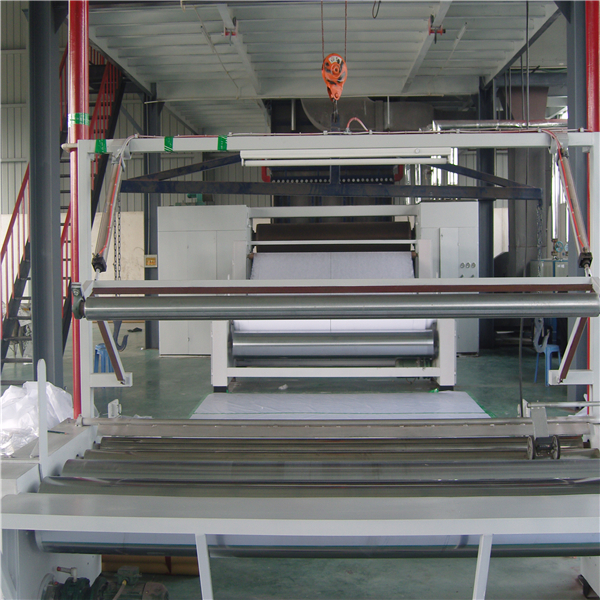

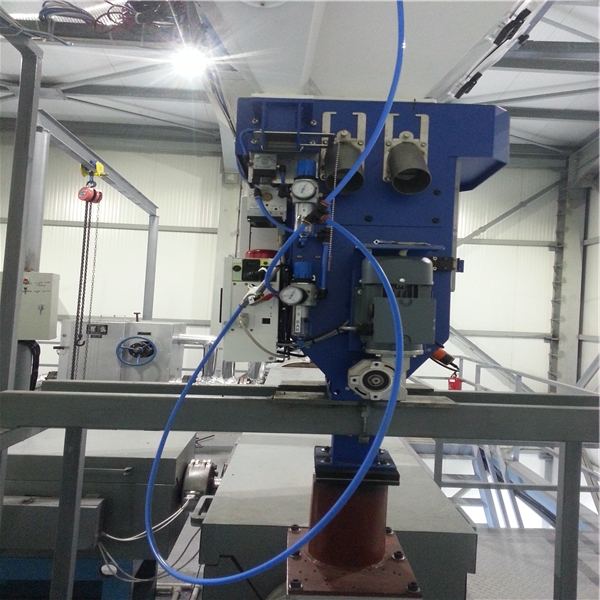

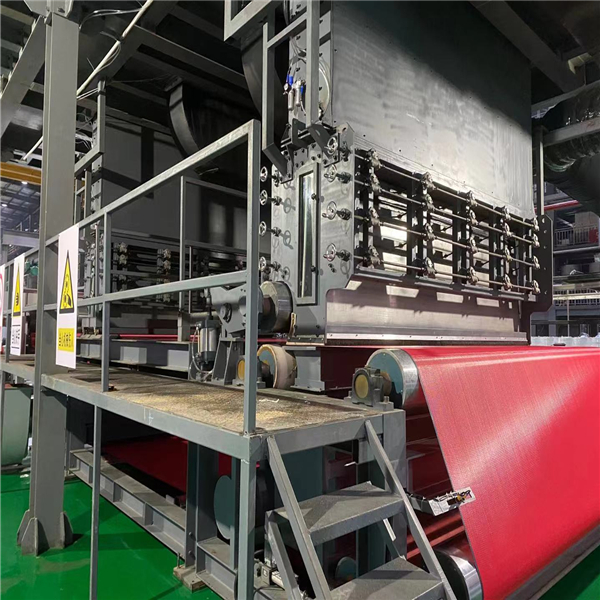

PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment

Our ss spunbond nonwoven production line adopts foreign advanced technology and experience,

Easy to operate, fully automated, PLC touch screen control, good product, high speed, high output. The equipment is usually 1.6 m wide, 2.4 m wide or 3.2 m wide, and it can also be customized according to the specific requirements of customers.

Product rendering

working principle

Product details

| SS(Prodnct width) | 1600mm | 2400mm | 3200mm |

| Equipment | 29x13x10m | 30x14x10m | 32x15x10m |

| Speed | 350m/min | 350m/min | 30m/min |

| Gram Weighht | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Yield(Products according to 20g/M2) | 9-10T/Days | 13-14T/Days | 18-19T/Days |

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

Our advantage

1. Adopting the uniform air spinning die head, the melt is evenly distributed.

2. The air pressure of the air nozzle is stable, the air flow on both sides is symmetrical, and the air flow in the width direction is uniform. The width of the air gap is easy to adjust.

3. The hot air heating device has good heating efficiency and excellent heat exchange efficiency, and low energy consumption.

4. The receiving distance is adjustable, and the receiving form (flat net receiving and roller receiving) can be easily changed.

5. The fiber size and cloth surface are uniform.

6. Static polarization treatment makes the melt blown cloth have a better filtering effect.

Application

Common application areas of non-woven fabrics:

1. Application in the field of air purification: used in air purifiers, as a high-efficiency air filter, and used for large-flow medium-efficiency air filtration. It has the advantages of low resistance, high strength, good acid and alkali corrosion resistance, stable efficiency, long service life, and low price.

2. Application in the medical field: The dust-proof mouth made of melt-blown cloth has low breathing resistance, is not stuffy, and the dust-proof efficiency is as high as 99%. It is widely used in hospitals, food processing, mines and other places where dust and bacteria prevention is required. The anti-inflammatory and analgesic film made of specially treated products has good permeability, no toxic side effects, and convenient to use. SMS products compounded with spunbond are widely used in the production of surgical gowns, caps and other sanitary products.

3. Liquid filter material and battery diaphragm: Polypropylene melt blown cloth has excellent performance in filtering acidic and alkaline liquids, oil, etc. It is regarded as a good diaphragm material in the battery industry at home and abroad, and has been Widespread use not only reduces the cost of the battery, simplifies the process, but also greatly reduces the weight and volume of the battery.

4. Oil-absorbing materials and industrial wipes: Oil-absorbing materials made of various polypropylene meltblown cloths have an oil-absorbing capacity of 14-15 times their own weight. They are widely used in environmental protection projects and oil-water separation projects. In addition, they can also be used as cleaning materials for oil and dust in industrial production. These applications give full play to the characteristics of polypropylene itself and the adsorption properties of ultrafine fibers prepared by melt spraying.

5. Heat insulation material: The average diameter of meltblown fiber is between 0.5-5μm, and it can be directly made into non-woven fabric by random spreading. Therefore, the specific surface area of the melt blown fiber is large and the porosity is high. A large amount of air is stored in this structure, which can effectively prevent heat loss. It is an excellent filtering and thermal insulation material. It is widely used in the production of clothing and various thermal insulation materials. Such as leather jackets, ski shirts, winter clothes, cotton cloth, etc., have the advantages of light weight, warmth, no moisture absorption, good air permeability, and no decay.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Short Lead Time for Mask Fabric Making Machine - PP melt blown cloth production equipment non-woven production line/melt blown cloth manufacturing machine equipment – Meiben , The product will supply to all over the world, such as: Mexico, Provence, Norway, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!