Due to the impact of the new crown epidemic in 2020, most industries have experienced a period of outage, and various economic activities have temporarily come to a standstill. In this situation, the non-woven fabric industry is busier than ever. As the demand for products such as disinfectant wipes and masks has reached unprecedented levels this year, news reports about the surge in demand for base materials (ie meltblown materials) have become mainstream, and many people have heard a new word for the first time-no Spun cloth, people began to pay more attention to the important role of non-woven materials in protecting public health. 2020 may be a lost year for other industries, but this situation does not apply to the non-woven industry.

01In response to Covid-19, companies increase production or expand their business scope to new markets

01In response to Covid-19, companies increase production or expand their business scope to new markets

It has been more than a year since Covid-19 cases were first reported. As the virus gradually spread from Asia to Europe and finally to North and South America in the first few months of 2020, many industries are facing suspension or closure. The non-woven fabric industry has begun to develop rapidly. Many markets for nonwoven services (medical, healthcare, sanitation, wipes, etc.) have been declared essential businesses for a long time, and there is an unprecedentedly high demand for medical equipment such as protective clothing, masks, and respirators. It also means that many companies in the industry must actually increase production or expand their existing businesses into new markets. According to Jacob Holm, a manufacturer of Sontara spunlace fabrics, as demand for personal protective equipment (PPE) increased in May, the production of this material increased by 65%. Jacob Holm has significantly increased production by eliminating defects in some existing lines and other improvements, and soon announced that a new global expansion factory will be established, which will be put into operation early next year. DuPont (DuPont) has been supplying Tyvek nonwovens to the medical market for many years. As the coronavirus drives the demand for medical materials, DuPont will transfer materials used in the construction market and other applications to the medical market. At the same time, it announced that it will be in Virginia. The state increased production capacity to rapidly produce more medical protective products. In addition to the non-woven industry, other companies that have not traditionally been involved in the medical and PPR markets have also taken quick actions to meet the growing demand caused by the new crown virus. Construction and specialty products manufacturer Johns Manville will also use meltblown materials produced in Michigan for face masks and mask applications, and spunbond nonwovens for medical applications in South Carolina.

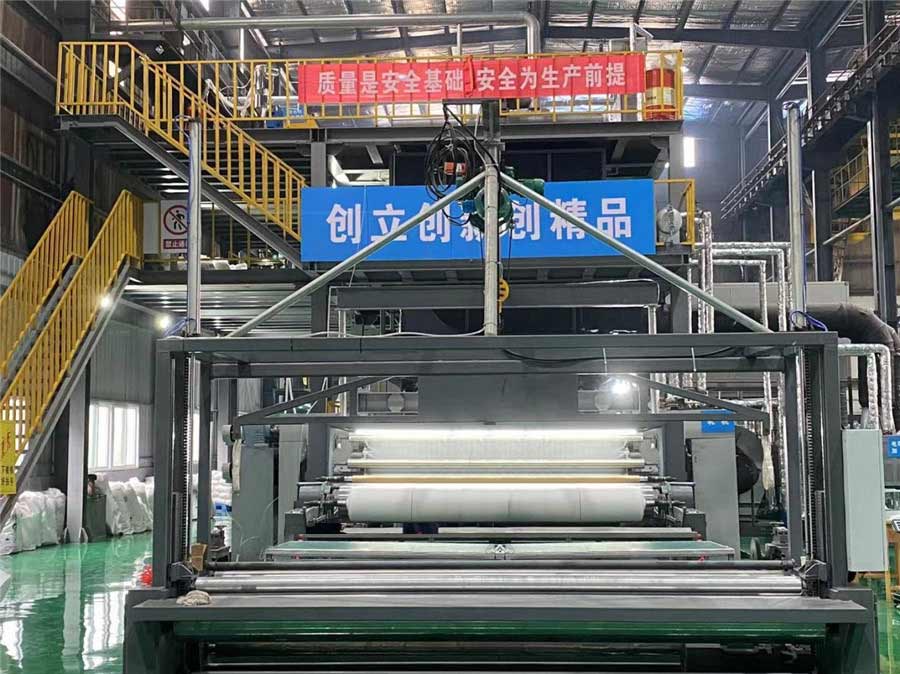

02Industry-leading nonwoven fabric manufacturers to increase meltblown production capacity this year

In 2020, nearly 40 new meltblown production lines are planned to be added in North America alone, and 100 new production lines may be added globally. At the beginning of the outbreak, the meltblown machinery supplier Reifenhauser announced that it could shorten the delivery time of the meltblown line to 3.5 months, thereby providing a fast and reliable solution to the global shortage of masks. Berry Group has always been at the forefront of meltblown capacity expansion. When the threat of the new crown virus was discovered, Berry had actually taken measures to increase meltblown capacity. At present, Berry has developed new production lines in Brazil, the United States, China, the United Kingdom and Europe. , And will eventually operate nine meltblown production lines worldwide. Like Berry, most of the world’s major nonwoven fabric manufacturers have increased their meltblown production capacity this year. Lydall is adding two production lines in Rochester, New Hampshire, and one production line in France. Fitesa is setting up new meltblown production lines in Italy, Germany and South Carolina; Sandler is investing in Germany; Mogul has added two meltblown production lines in Turkey; Freudenberg has added a production line in Germany. At the same time, some companies that are new to the nonwovens field have also invested in new production lines. These companies range from large multinational raw material suppliers to small independent start-ups, but their common goal is to help meet the global demand for mask materials.

03 Manufacturer of absorbent hygiene products expands its business scope to mask production

In order to ensure that there is sufficient nonwoven production capacity to meet the mask market demand, companies in various consumer markets have begun to increase the production of masks. Due to the similarities between the manufacture of masks and absorbent hygiene products, manufacturers of diapers and feminine hygiene products are at the forefront of these conversion masks. In April of this year, P&G announced that it would switch production capacity and begin manufacturing masks in nearly ten production bases around the world. Procter & Gamble CEO David Taylor said that mask production started in China and is now expanding to North America, Europe, Asia Pacific, the Middle East and Africa.

In addition to Procter & Gamble, Sweden’s Essity announced plans to produce masks for the Swedish market. South American health expert CMPC announced that it will be able to produce 18.5 million masks per month in the near future. CMPC has added five mask production lines in four countries (Chile, Brazil, Peru and Mexico). In each country/region, masks will be provided to public health services free of charge. In September, Ontex launched a production line with an annual production capacity of approximately 80 million masks at its Eeklo factory in Belgium. Since August, the production line has produced 100,000 masks per day.

04 The production volume of wet wipes has increased significantly, but there are still challenges in meeting the market demand for wet wipes

This year, with the surge in demand for disinfecting wipes, and the continuous introduction of new wipes applications in industry, personal and home care, investment in this area has been strong. In 2020, two of the world’s leading nonwoven fabric processors, Rockline Industries and Nice-Pak, both announced that they will significantly expand their North American operations. In August, Rockline said it would build a newest disinfecting wipes production line costing US$20 million in Wisconsin. According to reports, this investment will nearly double the company’s production capacity. The new production line, called XC-105 Galaxy, will become one of the largest wet wipe disinfection production lines in the private brand wet wipes industry. It is expected to be completed in mid-2021.

Similarly, wet wipes manufacturer Nice-Pak announced a plan to double the production capacity of disinfecting wipes at its Jonesboro plant. Nice-Pak changed the factory’s production plan to a 24 hours a day, 7 days a week production plan, thereby expanding production. Even though many companies have greatly increased the production capacity of wet wipes, they still face challenges in meeting the market demand for disinfection wipes. In November, Clorox announced an increase in production and cooperation with third-party suppliers. Although nearly one million packs of Clorox wipes are shipped to stores every day, it still cannot meet the demand.

05 The integration in the supply chain of the health industry has become a clear trend

In recent years, integration in the supply chain of the health industry has continued. This trend started when Berry Plastics acquired Avintiv and merged nonwovens and films, which are the two basic components of sanitary products. When Berry acquired Clopay, a manufacturer of breathable film technology in 2018, it even expanded its application in the film field. This year, another nonwoven fabric manufacturer Fitesa also expanded its film business through the acquisition of Tredegar Corporation’s Personal Care Films business, including a production base in Terre Haute, Indiana, Kerkrade, the Netherlands, Rétság, Hungary, Diadema, Brazil, and Pune, India. This acquisition strengthens Fitesa’s film, elastic materials and laminate business.

Post time: Jun-23-2021