China New Product Sss Fabric Nonwoven Spunbond Making Machine - Best Price SMS Surgical SMS Nonwoven Fabric machine High Standard Quality PP Spunbond Nonwoven Fabric Production Lin – Meiben

China New Product Sss Fabric Nonwoven Spunbond Making Machine - Best Price SMS Surgical SMS Nonwoven Fabric machine High Standard Quality PP Spunbond Nonwoven Fabric Production Lin – Meiben Detail:

The characteristics of medical and health textiles

1. Lightweight: Polypropylene resin is used as the main raw material for production, with a specific gravity of only 0.9, which is only three-fifths of cotton. It is fluffy and feels good;

2. Softness: It is composed of fine fibers (2-3D) and is formed by light-point hot-melt bonding. The finished product is moderately soft and comfortable;

3. Water repellent and breathable: Polypropylene slices do not absorb water, have zero moisture content, and have good water repellency. The fiber is composed of porous and good air permeability. It is easy to keep the cloth dry and easy to wash;

4. Non-toxic and non-irritating: The product is produced with FDA food-grade raw materials, does not contain other chemical ingredients, has stable performance, is non-toxic, has no peculiar smell, and does not irritate the skin;

Chemical resistance: Polypropylene is a chemically blunt substance, not moth-eaten, and can isolate the corrosion of bacteria and insects in the liquid; alkali corrosion, the finished product does not affect the strength due to erosion;

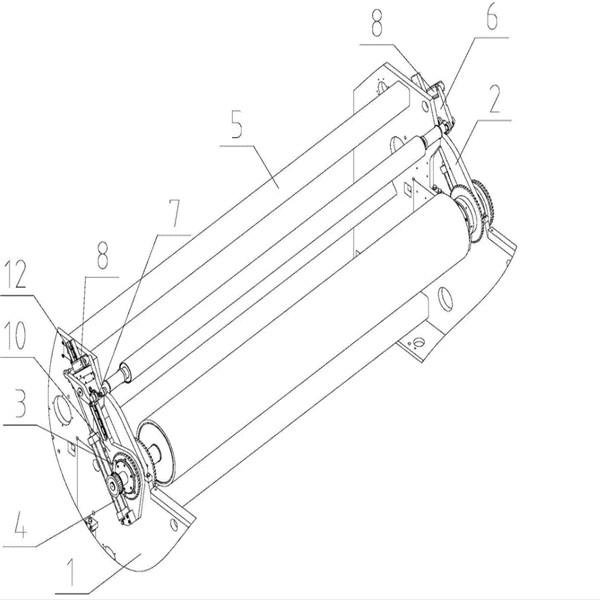

Equipment system diagram

Process technology of non-woven production line

Non-woven production line model

| SS(Prodnct width) | 1600mm | 2400mm | 3200mm |

| Equipment | 29x13x10m | 30x14x10m | 32x15x10m |

| Speed | 350m/min | 350m/min | 30m/min |

| Gram Weighht | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Yield(Products according to 20g/M2) | 9-10T/Days | 13-14T/Days | 18-19T/Days |

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

Equipment system diagram

What is non-woven fabric production machinery

non-woven fabric production machinery is a machine that makes non-woven fabrics into surgical gowns, protective clothing, masks, space cotton, insulation materials, filter cotton and other finished products. Including a series of non-woven machines such as mask machines for the production of masks, surgical gown machines for the production of surgical gowns, and filter cotton weaving machines for filter cotton. Equipment for processing non-woven fabrics to produce various products, including: non-woven bag machine, non-woven pillow cover machine, non-woven fruit cover machine, non-woven strip cap machine, non-woven doctor Hat machine and so on. Non-woven fabric production machinery pays attention to equipment processing accuracy and selection of new materials, improves the level of mechanical and electrical integration, and further applies computer online detection and control and network systems to ensure high yield and high quality production. Non-woven fabric production machinery should develop towards versatility, combination and differentiation, and biodegradable fiber non-woven fabric products.

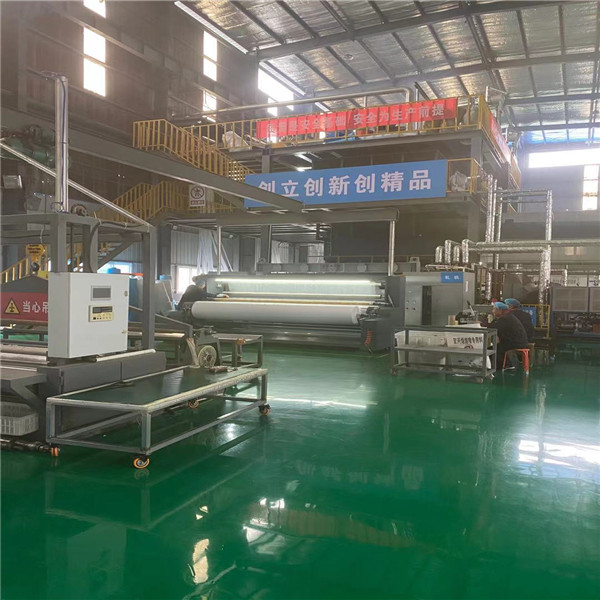

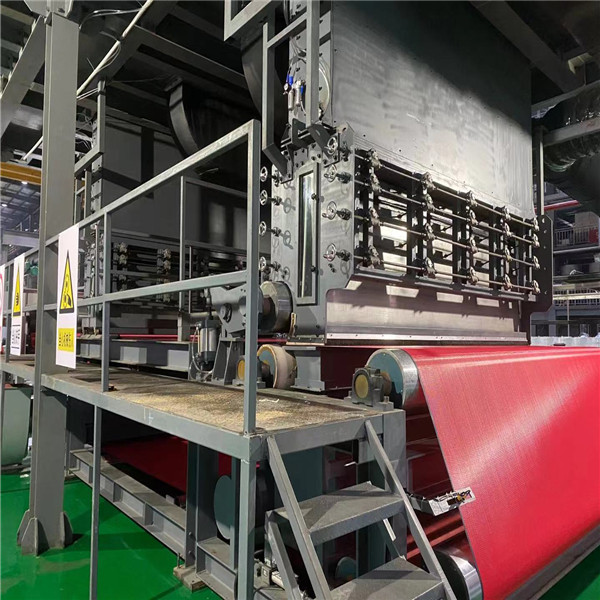

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for China New Product Sss Fabric Nonwoven Spunbond Making Machine - Best Price SMS Surgical SMS Nonwoven Fabric machine High Standard Quality PP Spunbond Nonwoven Fabric Production Lin – Meiben , The product will supply to all over the world, such as: Burundi, Nairobi, Danish, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.